Für welches Thema interessieren Sie sich?

Wir betreiben Forschung mit Wirkung

Mit unserer Forschung greifen wir die Zukunftsthemen der Druck- und Medientechnologien auf. Die Forschungsgegenstände entwickeln sich aus dem kontinuierlichen Dialog mit den Unternehmen und orientieren sich an ihren Anforderungen. Dabei selbstverständlich: Unsere Forschung schließt immer den Anwendungstransfer ein.

Erfahren Sie alles zu unseren aktuellen Forschungsschwerpunkten und -projekten.

Unsere Kernkompetenzen

Prüfungsleistungen

Mit der Fogra sind Sie gut beraten.

Wir verstehen uns als moderner Dienstleister:

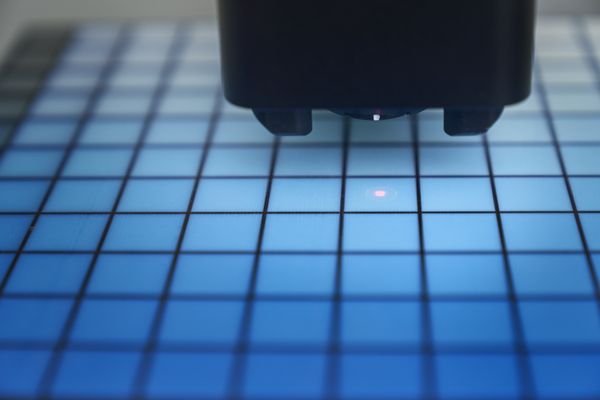

Wir führen aussagekräftige Prüfungen durch

Unternehmen beraten wir zu Qualitätsfragen

In fachlichen Streitfällen schlichten wir.

Das Anwendungsfeld reicht von kundenindividuellen Fragestellungen bis hin zu standardisierten Labormessungen.

Zertifizierungsleistungen

Das modulare Testprogramm FograCert

Verschiedene Materialien, Produkte und Produktionsprozesse werden einem standardisierten FograCert-Testprogramm unterzogen. So können wir die Qualität bei der Verarbeitung der Materialien, bei hochqualitativen Produkten und verlässlichen Herstellungsprozessen mit einem Fogra-Zertifikat bestätigen. Fachkräfte können ein Zertifikat über ihre Qualifikation erhalten.

Eine Auswahl unserer Zertifizierungen:

ProzessStandard Offsetdruck (PSO)

ProzessStandard Digitaldruck (PSD)

Freigaben für Feucht- und Reinigungsmittel

Fakten

900 Mitgliedsunternehmen aus 50 Ländern

1.600 Systeme zertifiziert

22.000 Symposiumsteilnehmerinnen und -teilnehmer seit 1978

33.000 Gutachten seit 1951

Neuigkeiten

Stories

Inside Fogra

STORIES

Fünf Tage, fünf Abteilungen. Schülerpraktikantin Zoe durfte jeden Tag in einen anderen Bereich hineinschnuppern. Dabei hat sie viel gelernt und erfahren. Sie durfte Vliese testen, hat Papiere nach dem Anteil der optischen Aufheller sortiert und konnte sich die Druckmaschine anschauen.

Type 1 Fonts

STORIES

Keine Type 1 Fonts mehr. Was können Sie tun, welche Maßnahmen treffen, welche Alternativen nutzen? Im Colour Management Café wurden diese Fragen und viele mehr diskutiert und Lösungen besprochen. Erfahren Sie mehr, welche Vorschläge die drei geladenen Experten gemacht haben.

Unser Institut

STORIES

Zum Forschen, Prüfen und Zertifizieren braucht es maßgeschneiderte Räume mit modernster Laboreinrichtung. Neben der perfekten technischen Ausstattung spielt aber auch die raumplanerische Komponente eine wichtige Rolle. Die Arbeitsumgebung muss es den Mitarbeiterinnen und Mitarbeitern ermöglichen, Ideen zu entwickeln und sich interdisziplinär zusammenzufinden. Wir haben dafür ideale Voraussetzungen geschaffen.

Gründungsmitglied von