Topic of your interest

Certification according to PSO (ISO 12647)

With a certification according to PSO (ISO 12647), printing companies ensure a smooth process internally. Externally, they demonstrate their ability to produce in accordance with the high quality requirements of the internationally recognized standard and to comply with the colour specifications of their customers.

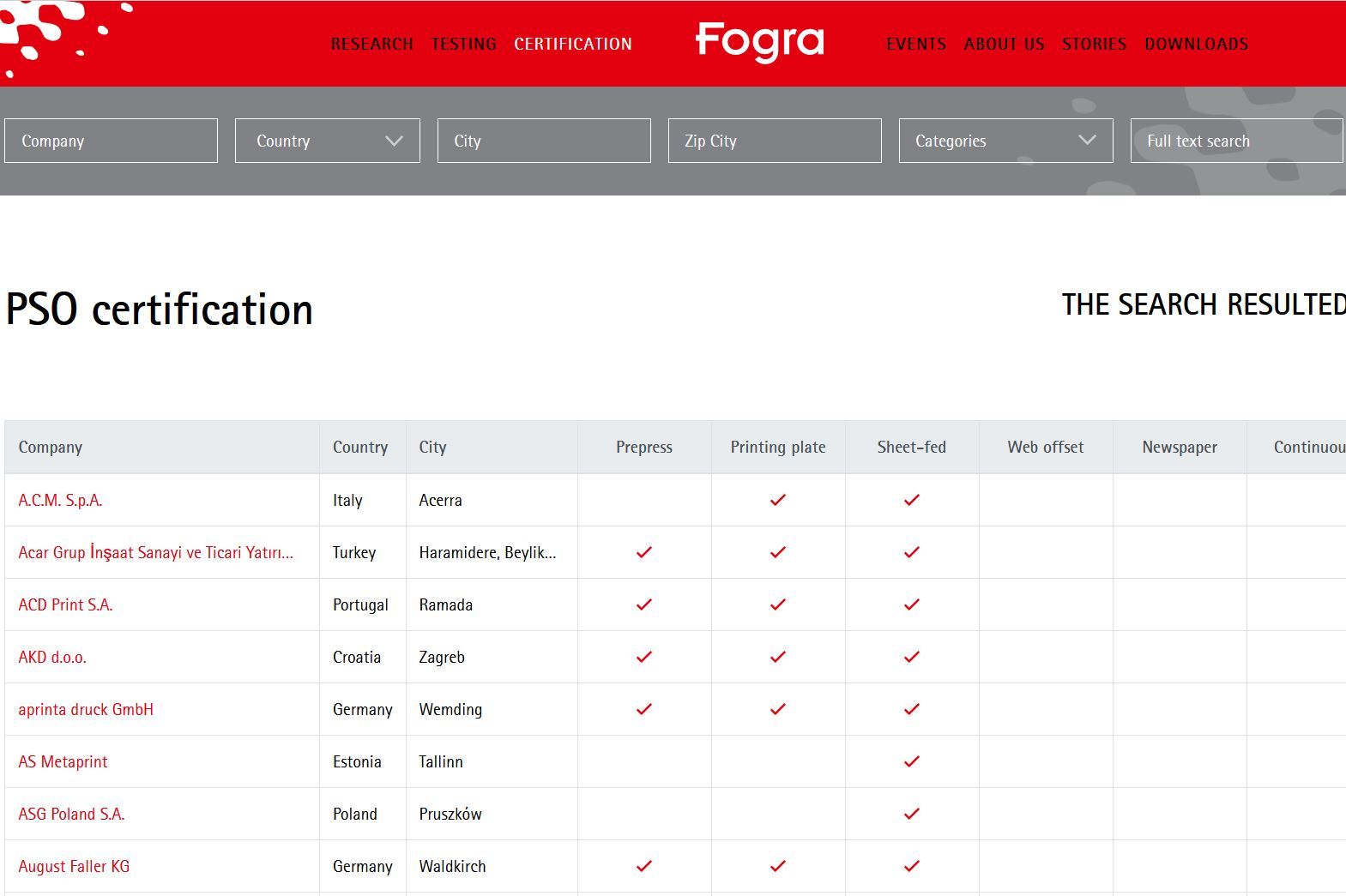

Furthermore, your company will be listed in the Fogra PSO database. This database can be checked by quality conscious customers and agencies looking for suitable printers in their vicinity.

What you need to do

General examinations

Preflight check tools must be used to find errors in a PDF test file.

Qualified colour management

The focus is on the correct handling of colour transformations with ICC profiles. In addition, tools for monitor profiling must be presented.

Proof creation

Digital proofs shall be produced to simulate various printing conditions and checked for colour accuracy.

Platemaking

It shall be demonstrated that appropriate control mechanisms are applied to ensure that the platemaking is consistent. Suitable correction tables must be stored in the CTP RIP in order to achieve the tone value increases required in print.

Print job make-ready/print run

An acceptance test form is printed on a selected printing machine. The printing substrate is chosen by the printer and must be assigned to the existing paper categories. A short production run is used to randomly evaluate the constancy of the print run.

Our procedure

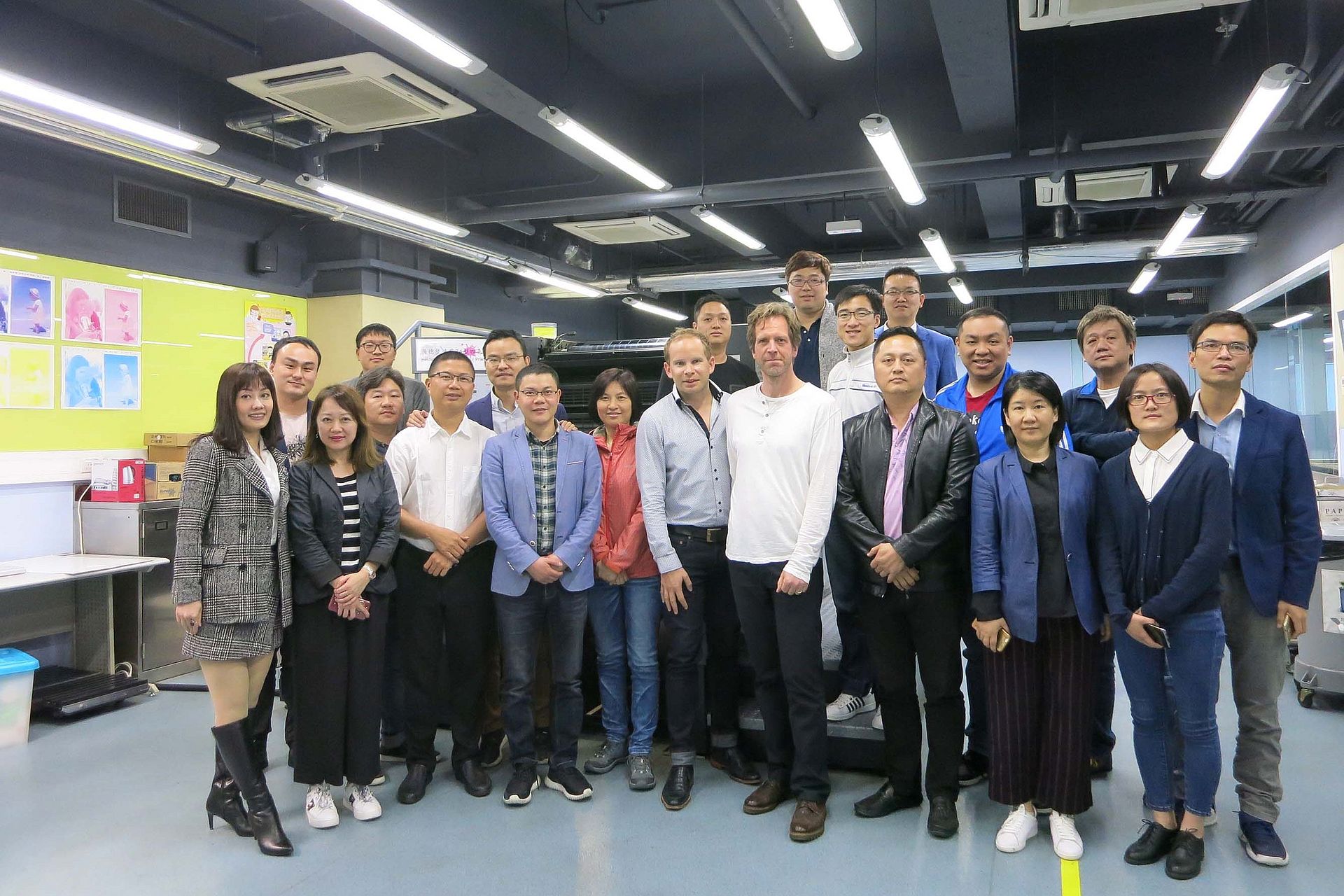

A Fogra employee is on site for a short day to carry out the test programme. As alternative the test can also be performed online. Using test forms and data sets, the workflow from prepress to print is followed. The printed copies produced are then evaluated by Fogra.

The intermediate test takes place without Fogra staff. Instead, the print shops will send some printed copies to Fogra for evaluation.

Step by step to PSO certification

Please take a few minutes, fill in the questionnaire and send it to Fogra. It will serve as a preliminary check for us in order to determine the next steps. At the same time it is a check for you of the procedures and process components that will be queried during the test. As soon as we have received the questionnaire, a member of staff will contact you.

Main examination (plus travel expenses in case of onsite variant)

Sheet-fed or web: € 3,180 (€ 2,340 for Fogra members with 20 or less employees)

Sheet-fed and web: € 5,570

Prepress only (without CTP): € 2,120

Intermediate test

Sheet-fed or web: € 500

Sheet-fed and web: € 1,000

Prepress only (without CTP): € 150